I. equipment introduction

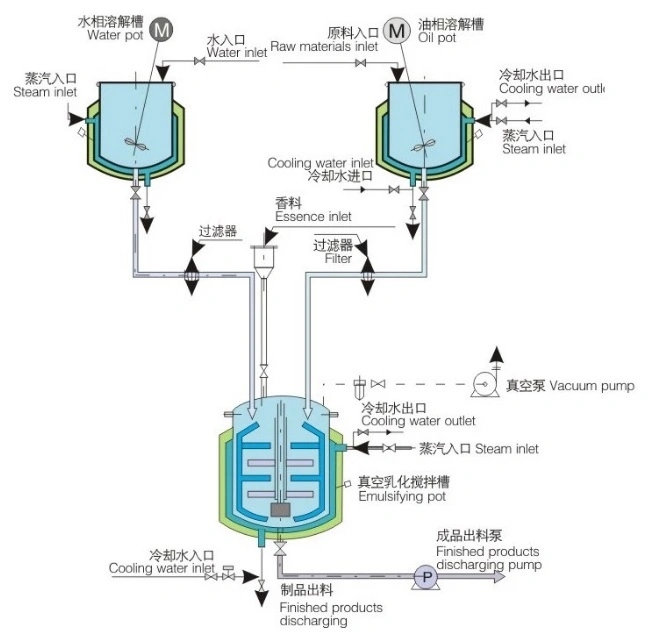

Vacuum emulsifier is mainly composed of emulsifier, vacuum system, lifting system, electrical control system, etc.

\

APPLICATIN

The equipment is mainly used in daily chemical care products, biomedicine, food industry, coating ink, nano materials, petrochemical industry, printing and dyeing auxiliaries, paper industry, pesticide and chemical fertilizer, plastic rubber, power electronics, other fine chemicals, etc., especially for material emulsification configuration with high matrix viscosity and solid content.

II. Equipment features

★ the company produces various types of vacuum emulsification, in which the homogenization system is divided into upper homogenization, lower homogenization, internal and external circulation, and the mixing system is divided into single-phase mixing, two-way mixing and spiral mixing; and it can customize various qualified and high-quality products according to customer requirements;

★ frequency converter is used for speed regulation of mixing, which can meet the production requirements of different processes;

★ homogeneous structure of German technology, with imported double face mechanical seal effect

★ vacuum defoaming makes the materials meet the aseptic requirements, and vacuum suction is used, especially for powder materials to avoid dust flying;

★ the lifting device can be selected for the main pot cover, which is convenient for cleaning and has more significant cleaning effect. The pot body can be selected for dumping;

★ the pot body is composed of three layers of stainless steel imported plate welding, and the tank body and pipeline are mirror polished, fully in line with GMP requirements;

★ according to the process requirements, the tank body can heat and cool the materials, and the heating methods mainly include steam and electric heating;

★ in order to ensure the requirements of the whole customer, the electrical appliances can be imported configuration, which can completely meet the international standards.

Main pot

| No. | Method | Specification | Remarks |

| 1 | Stirring method | 1.one way scraping agitator blade ,power 4 KW,speed 0-63r/min | frequency control scrap wall material :polytetrafluoroethylene |

| 2.homogenizer power 7.5KW, speed 0-3000r/min | Frequency control | ||

| 2 | Sealing process | Machinery Seal | |

| 3 | Inlet material | Vacuum suction | |

| 4 | Discharge material | Pneumatic or direct ball valve | |

| 5 | Temperature shows | resistance thermometer(≤200ºC) | |

| 6 | Pressure and vaccum | Vacuum gage ,max-0.08Mpa | |

| 7 | Heating cooling method | Bottom electric heating, jacket water cooling, heating power: 18kw. | |

| 8 | Main technique | 1.working pressure of jacket 0.1Mpa | |

| 2.design volume 625L | |||

| 3.working volume 200-500L | |||

| 9 | Material | 1.contact material all is 316L,Thickness 5mm | Inside polishing |

| 2.jacket SUS316L,thickness 4mm | Insulation temperature :aluminum fiber cotton | ||

| 3.out shell pot material 316L,thickness 3mm | Outside polishing | ||

| 10 | Polishing process | More than 300m on polishing | |

| 11 | Cover area | 3350mm*3250mm*2710mm | |

| 12 | Higher | 2710mm | |

| 13 | Others | The parts contact material all is imported 316l ss |

Oil pot

| No. | Method | Specification | remarks |

| 1 | Stirring method | Bottom dispersion,power 1.5KW,speed 960r/min | |

| 2 | Boil pot open | Half open | |

| 3 | Discharge method | By ball valve | |

| 4 | Temperature shows | resistance thermometer(≤200ºC) | |

| 5 | Main technique | 1.bottom electric heating,heating power :18kw working pressure<0.1Mpa | |

| 2. design volume 275L, working volume 200L | |||

| 6 | Material | 1.inside pot 316L | Inner polishing |

| 2.jacket material 304 | Insulation temperature :aluminum fiber cotton | ||

| 3.outside material 304 | Outside polishing | ||

| 7 | Polishing | More than 300m polishing result |

water pot

| No. | Method | Specification | Remarks |

| 1 | Stirring method | Bottom dispersion,power 1.5kw, speed 960r/min | |

| 2 | Boil pot open | Half open | |

| 3 | Discharge method | By ball valve | |

| 4 | Temperature shows | resistance thermometer(<200ºC) | |

| 5 | Main technique | 1.bottom electric heating,heating power :18kw working pressure<0.1Mpa | |

| 2. design volume 45L; working volume 300L | |||

| 6 | Material | 1.inside pot 316L, | Inner polishing |

| 2.jacket material 304 | Insulation temperature :aluminum fiber cotton | ||

| 3.outside materail 304 | Outside polishing | ||

| 7 | Polishing | More than 300m polishing result |

| No. | Name parts | Specification | Remarks |

| 1 | Stand hold and platform | ss stand hold ,decorative pattern ss sheet | |

| 2 | Emulsifying pot | Include inlet outlet ,manhole,thermometer ,material filter, spice bucket etc | |

| 3 | Pipe | Contact materail pipe all 316l ss | |

| 4 | Electric control cabinet | Whole ss make ,control main pot ,oil ,water pot | Push buttom by hand |

Power consumption

| Name | Specification | Remarks |

| 500Lemusifying pot | 1.framed scraping wall paddle4KW | |

| 2.homogenizer7.5KW,bottom homogenizer, heating power :18kw | ||

| 500L oil pot | Pulwheel propeller,1.5KW,heating power :18kw | |

| 500L water pot | Pulwheel propeller ,1.5KW,heating power:18kw | |

| Vacuum pump | 2.85KW | |

| Voltage | 380V/50HZ 3Phase |

| No. | Name | Brand or orgin place | Remarks |

| 1 | Inverter | DELIXI | |

| 2 | Motor | SIEMENS | |

| 3 | Electic button | DELIXI | |

| 4 | Vacuum pump | ZIBO | |

| 5 | Main electric components | DELIXI |

FAQ

1. Is your company a manufacturer or trading company?

A1: We are a professional manufacturer, specializing in designing and manufacturing whole set of equipment for daily chemical, pharmaceutical and chemical industry, and we also supply heat ex-changer, LNG vehicle cylinders, as well as related technical service.

2. Where is your company? How can I get there?

A2: We are in Gaoyou City, Jiangsu Province, China. It takes about 4 hours By car or bus from Shanghai Airport, and High speed train rail way station will be put in use at the end of 2020, which will be helpful to shorten the time to Shanghai.

3.What is your quality control procedure?

A3: We strictly follow ISO9001 QC procedure and we have got the TUV and ISO certificates. Moreover, before shipment, we carry out tests and inspections for each machine. Customers can also come for supervising.

4.What are your core business?

A4: We are a specializing in designing and manufacturing whole set of equipment for daily chemical, pharmaceutical and chemical industry, and we also supply heat exchanger, LNG vehicle cylinders, as well as related technical service.

5.How long is your lead time if I place order?

A5: Usually no longer than 30 days.

6.What is your payment term?

A6: 30% advance payment against PO, 70% balance after testing and before shipment. We accept LC at sight, TT, PayPal, etc.

7.What is your warranty? And how is your after-sales service?

A7: We offer one-year warranty. During this warranty, if there is any part with issue due to machine itself and isn't caused by improper operation, we will provide new spare part at our cost. Furthermore, we provide lifelong after-sales services for our machines and we supply spare parts with cost prices for future maintenance/repairs.